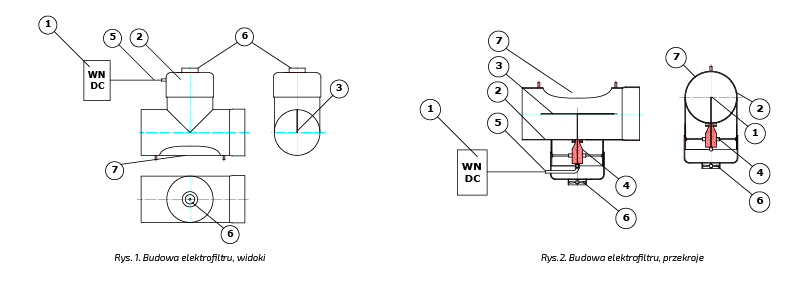

The operation of the electro filter (Figs. 1 and 2) is possible due to the high voltage generator (1) generating direct current. The electro filter’s body (2) is made from carbon steel. The body has a mounted corona electrode (3) generating corona discharges, made from steel wire. The electrode is placed centrally in the flue gas duct with the use of a fastening bar with a ceramic insulator (4). The system of the insulated electrode is fed with high voltage from the HV generator (1) by an adequately insulated power supply cable (5). The discharging electrode, the surface of separation consists of earthed walls of the electro filter’s body and the chimney duct where the electro filter is mounted. The interior of the body where the electrode is mounted is ventilated with shielding air by means of a fan (6). It is possible to manually clean and maintain the electro filter through the inspection opening (7). Depending on the version, upon the customer’s request, the electro filter may also be equipped with a system of automatic cleaning for the collecting electrode (not presented in the figures).

The separation of dust from the stream of dusty flue gas and the sedimentation on the surface of the collecting electrode, the body’s walls, takes place due to the electrostatic force. The grains of dust obtain an electrostatic load as a result of collisions with gas ions the source of which are unipolar electrical discharges generated on the corona electrode. As a result of gas ionization and further dust grains, the particles of dust proceed towards the collecting electrode. The effectiveness of the electro filter’s operation is the basic parameter characterizing its usability. The effectiveness of the simplest solutions may vary between 60% and 90% depending on the type and quality of the emission source.

The discussed method of dust removal from flue gas from low-power combustion installations (furnace, boiler) is the BAT solution (best available technique) from the technical point of view. It guarantees the fulfilment of increasingly higher energy-emission requirements formulated for low-power combustion installations (also those specified in relevant testing standards EN303-5 as well as EN13289). Depending on dust emission relevant for a given source, boiler or furnace, the application of a highly efficient dust extraction unit, namely the electro filter, makes it possible to shift the device from class 3 according to standard 303-5 to class 4 or even 5 with regard to dust emission. This corresponds to dust emission at the level below 40 mg/mn3.